JIB CRANES

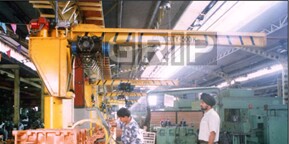

Jib cranes are an economical solution for moving materials within an individual workstation, for transferring materials from work area to work area or for serving as auxiliary lifting devices under overhead cranes.

Styles range from entirely self-supporting to styles that mount to existing building columns, resulting in low costs compared to some overhead lifting systems. Because they are self-supporting, free standing jib cranes are well suited for outdoor use and can be fully weatherized.

“GRIP” range of Jib Cranes consists of the following:-

“GRIP” range of Jib Cranes (360º/200º Degree of rotation, Capacity up to 10 Tons & 8.0 mtr. Jib Radius) consists of the following:-

- BASE MOUNTED TYPE:-

- 360o rotation

- The pipe mast or column is designed to give maximum strength and minimum deflection to resist bending, buckling, and crushing as well as wear by the guide roller assembly.

- GRIP Jib cranes are designed to be mounted to a permanent concrete foundation which, in addition to anchoring the crane, acts basically as a counter weight for the forces exerted by the crane under maximum loading conditions.

|

|

- Bracket Mounted Jib Crane:-

- 200o rotation

- Offers greatest potential underboom clearance because it can be installed more closely to the ceiling than other wall mounted style.

- Allows maximum usage of the work area, including work close to the existing structure, because there are no supporting components under the boom.

- Option of Bracket mounted tie rod supported style Jib crane is also available provided, overhead clearance is not a limiting factor.

|

|

- Wall Travelling Jib Cranes:-

- Custom engineered as a perfect complement to an overhead crane system to perform tasks efficiently without tying up an overhead crane, also they can be used to cover a series of workstation with little or no downtime waiting for an overhead crane availability.

- These cranes do not rotate but travel on runway tracks suspended along building / shed columns and requires special design of runway tracks & columns.

|

|